Planning a construction project can feel like a huge puzzle. You need to know how many yards of concrete in a truck to get the job done right. If you order too little, your project stops halfway through. If you order too much, you waste money and materials. This guide will help you understand truck sizes and load limits. We will make sure your next pour goes perfectly without any stress.

Understanding the Standard Concrete Truckload

When you see those big spinning drums on the road, you are looking at a ready-mix truck. These machines are the backbone of the building world. They keep the mix moving so it stays fresh and usable. Understanding their capacity is the first step to a successful project.

The Industry Average Capacity

- Maximum drum size is usually around 10 to 12 cubic yards for a standard mixer truck.

- Practical delivery loads typically fall between 8 to 10 cubic yards to avoid messy spills on the road.

- Small project loads can be adjusted based on what the specific ready-mix plant offers for its fleet.

- Standard truckloads are the most cost-effective way to buy concrete for larger residential jobs.

The Volume-to-Weight Relationship

- Cubic yard weight for standard concrete is approximately 4,056 pounds.

- Total payload weight for a full 10-yard truck is over 40,000 pounds.

- Vehicle weight must be added to the product weight to calculate the total impact on a driveway.

- Weight distribution is handled by multiple axles to keep the truck stable during transport.

Diverse Types of Concrete Trucks and Their Specific Capacities

Not every job site can fit a massive 10-yard truck. Some projects need a more surgical approach to placement. Choosing the right vehicle type saves time and prevents site damage.

Standard Rear-Discharge Mixers

- Common usage makes these the go-to choice for most residential driveways and commercial slabs.

- Chute system allows the mix to flow out the back into your forms or a pump.

- Maneuvering requires a skilled driver to back the heavy truck into the perfect spot.

Front-Discharge Concrete Trucks

- Driver control is better because the operator can see the pour from the cab.

- Efficiency increases on curb-and-gutter work where the truck moves forward constantly.

- Direct placement is easier since the chute sits over the front bumper.

Volumetric Mixers (On-Site Mixing)

- Raw materials like sand, gravel, and Portland cement are kept in separate bins.

- Mixing on-demand means the concrete is always fresh when it hits the ground.

- Zero waste is a huge benefit because you only pay for what you actually use.

Mini-Mix and Portable Trucks

- Tight spaces are easy to navigate with these smaller, nimble vehicles.

- Mini-mix capacity usually stays between 1 to 2 cubic yards per trip.

- Small jobs like fence posts or hot tub pads are perfect for these trucks.

High-Capacity Industrial Trucks

- Massive pours for bridges or factory floors require these heavy-duty units.

- Maximum capacity can reach up to 12 cubic yards for specialized industrial loads.

- Permitting is often required because these trucks exceed standard road weight limits.

Critical Factors Influencing Actual Truck Capacity

The physical size of the drum is not the only thing that matters. Laws and safety rules play a big part in how much concrete shows up. You should check your local rules before the truck arrives.

Legal Weight Limits and Road Restrictions

- State weight regulations often limit how much a truck can legally carry on public roads.

- Bridge laws restrict heavy loads to protect the structural integrity of local overpasses.

- Residential streets may have specific weight caps that prevent a full 10-yard delivery.

The Impact of Concrete Mix Density

- Lightweight concrete uses different aggregates which might allow for a larger volume per load.

- High-strength mixes can be denser and heavier, requiring smaller volume loads to stay legal.

- Air additives change the volume of the mix by adding tiny bubbles to the slurry.

Job Site Accessibility and Terrain

- Soft soil can cause a heavy truck to sink or tip over during the pour.

- Steep inclines make it dangerous for a full drum to rotate safely while driving.

- Overhead obstructions like power lines or trees can block large trucks from entering.

Technical Specifications: Slump, Mix, and Consistency

The “thickness” of your concrete changes how it behaves in the truck. This is known as the slump of the mix. It affects both the delivery and the final finish of your work.

Understanding Slump and Its Effect on Volume

- Wetter mixes have a higher slump and flow more easily through the truck chute.

- Splashing is a risk with high-slump concrete, so drivers may carry less per load.

- Stiff mixes are harder to discharge and might require more time to empty the drum.

Specialty Mixes and Volume Displacement

- Fiber-reinforced concrete adds strength but can change how the mix yields in the drum.

- Colored concrete requires careful cleaning of the truck to ensure the hue is perfect.

- Stamped concrete needs a specific consistency to hold the patterns during the set time.

How to Calculate the Concrete Needed for Your Project

You do not want to guess when it comes to ordering. Knowing how many yards of concrete in a truck is only half the battle. You also need to know the volume of your project area.

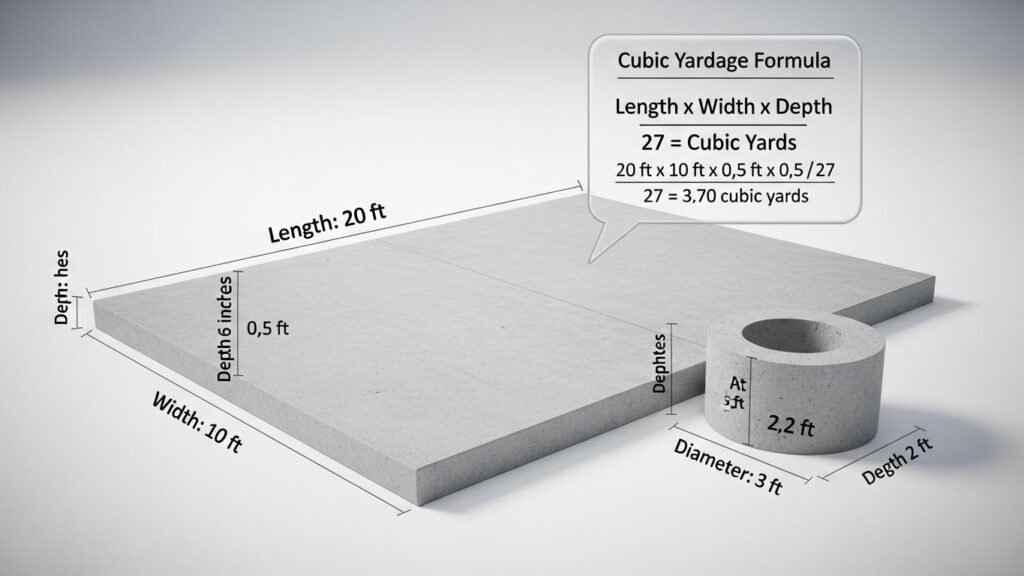

The Cubic Yardage Formula

- Volume calculation starts with multiplying the length, width, and depth in feet.

- Conversion factor requires you to divide that total cubic feet by 27 to get yards.

- Square foot area should be double-checked to ensure your measurements are precise.

Geometry-Specific Calculations

- Circular pillars use the radius squared times pi times the height for volume.

- Sonotube footings are common for decks and require careful yardage estimates.

- Thickened edges on a slab-on-grade foundation add extra volume that many people forget.

The Importance of the 5–10% Waste Margin

- Spillage happens naturally during the transfer from the truck to the forms.

- Uneven subgrades can swallow up more concrete than your flat measurements suggest.

- Wastage allowance protects you from having to order a second, expensive short load.

Delivery Logistics and Cost Management

Getting the concrete to your site is a dance of timing and money. You want to be ready the moment the driver pulls up. Delays can be very expensive in this business.

Understanding the Short Load Fee

- Minimum orders are usually required by ready-mix plants to cover their fuel costs.

- Short load fees apply if you order less than 4 or 5 cubic yards at once.

- Cost-effectiveness is highest when you can take a full truckload of 10 yards.

Coordination with Ready-Mix Suppliers

- Delivery distance from the plant affects how long the concrete stays fresh in the drum.

- Fresh concrete has a limited window of about 90 minutes before it starts to set.

- Clear communication about your site helps the dispatcher send the right size truck.

Distance, Travel Time, and Hot Loads

- Chemical reactions start the moment water hits the Portland cement in the mixer.

- Ambient temperature can speed up the set time, especially during hot summer days.

- Set retarders can be added to the mix if the travel time is exceptionally long.

On-Site Discharge: Moving Concrete from Truck to Form

Once the truck arrives, the real work begins. You need a plan to get the wet mud into the right spot. The method you choose depends on your budget and site layout.

Direct Discharge via Chute

- Standard chutes reach about 12 to 18 feet from the back of the truck.

- Placement is restricted to areas where the truck can drive right up to the edge.

- Extension chutes can sometimes be added for a bit of extra distance.

Utilizing Concrete Pumps (Boom and Line Pumps)

- Obstacles like houses or fences are easy to bypass with a pump truck.

- Line pumps use flexible hoses to snake through narrow yards to reach the back.

- Boom pumps use a large hydraulic arm to lift concrete over the top of buildings.

Power Buggies and Wheelbarrows

- Manual transport is slow and requires a lot of labor to finish the pour.

- Truck standby fees might be charged if you take too long to unload the drum.

- Consistency is hard to maintain if the first half of the pour sets before the last half arrives.

Environmental and Weather Considerations

Mother Nature has a big say in your concrete project. You should always check the forecast before booking your delivery. Weather can change the quality of your finished slab.

Pouring in Extreme Heat vs. Cold

- Hydration happens faster in the heat, which can lead to cracks if not managed.

- Heated water is often used by plants in the winter to keep the mix from freezing.

- Ice addition is a trick used in the summer to keep the drum temperature down.

Managing Rain and Humidity

- Excess moisture from rain can ruin the water-to-cement ratio of your mix.

- Surface finish is hard to achieve if it is pouring rain during the final troweling.

- Covering the slab with plastic helps protect the fresh concrete from light showers.

Post-Delivery: Cleanup and Excess Concrete

The job is not finished when the truck is empty. There are rules for how to clean up and handle what is left. Being a good neighbor means keeping the street clean.

Washout Procedures and Environmental Regulations

- Toxic slurry from cleaning the drum must be contained in a designated washout pit.

- Environmental regulations prevent drivers from washing out into storm drains or creeks.

- OSHA and MSHA guidelines ensure that the cleanup process is safe for all workers.

What to Do with Leftover Concrete

- Small projects like fence posts are a great way to use up the last bit of mud.

- Stepping stones can be made quickly using simple molds and leftover mix.

- Disposal fees might be charged if the truck has to take a large amount back to the plant.

Professional Planning Tools and Resources

Do not be afraid to ask for help when calculating your needs. There are many modern tools designed to make this easy. Accuracy is the best way to save money on your build.

Using Concrete Calculators and Mobile Apps

- Digital tools allow you to input dimensions and get an instant yardage count.

- Mobile apps are handy for making quick adjustments while you are standing on the job site.

- Accuracy is much higher with these tools than doing the math by hand on a napkin.

Seeking Professional Quotes and Site Surveys

- Free quotes from local suppliers give you a clear idea of the total delivery cost.

- Site walks by a contractor help identify issues with truck access or weight limits.

- Expertise from experienced concrete workers ensures your foundation is built to last.

| Truck Type | Typical Capacity (Yards) | Best Use Case |

| Standard Mixer | 8 – 10 | Driveways and Slabs |

| Volumetric Mixer | Variable | Remote Sites / Zero Waste |

| Mini-Mix | 1 – 2 | Fence Posts and Patios |

| Industrial Truck | 10 – 12 | Large Commercial Pours |

Knowing exactly how many yards of concrete in a truck helps you stay on budget. Always measure twice and work closely with your local ready-mix plant. With the right planning, your next concrete pour will be a total success.

Frequently Asked Questions About Concrete Truck Deliveries

This section addresses common queries that project managers and homeowners often have when planning a concrete pour. These details provide further clarity on technical logistics and industry standards.

What is the maximum distance a truck can travel from the plant?

Most ready-mix plants aim to keep travel time under 60 to 90 minutes to prevent the concrete from setting in the drum. If a project is further away, chemical retarders must be added to the mix to slow down the hydration process.

How much space does a concrete truck need to turn around?

A standard mixer truck requires a turning radius of approximately 35 to 40 feet. You must ensure the construction site has enough clearance for the vehicle to maneuver without hitting structures or getting stuck in soft soil.

Can a concrete truck drive over my existing sidewalk?

It is not recommended because a full truck weighs over 60,000 pounds and can easily crack residential concrete. Most sidewalks and driveways are only designed to hold light passenger vehicles, not heavy industrial equipment.

What is a standby fee and how is it calculated?

Ready-mix companies usually provide a specific amount of free time for unloading, often 6 to 10 minutes per yard. If the truck sits at your site longer than the allotted time, you will be charged a standby fee per minute.

How do I prepare my driveway for a heavy truck delivery?

You should ensure the ground is compacted and dry to prevent the truck from sinking. If the ground is soft, you might need to lay down heavy plywood or timber mats to distribute the weight of the vehicle.

Is there a difference between a concrete mixer and a cement truck?

Yes, though the terms are used interchangeably, cement is actually just an ingredient in concrete. The vehicle is technically a concrete mixer truck because it carries a blend of cement, water, and aggregates.

Can I ask the driver to add more water to the mix on-site?

Drivers can add water to increase the slump, but this can weaken the final strength of the concrete. It is best to consult with a contractor before changing the water-to-cement ratio at the job site.

What happens to the drum during a breakdown?

If the truck breaks down and the drum stops spinning, the concrete will begin to harden inside. In these cases, workers may have to manually chip out the hardened concrete, which is a costly and difficult maintenance task.

Does the color of the truck drum matter?

Most drums are painted white or a light color to reflect sunlight and keep the concrete mix cool. Heat can cause concrete to set too quickly, so maintaining a lower temperature inside the drum is critical for quality.

What is the height clearance of a standard concrete truck?

A typical mixer truck stands about 12 to 13 feet high. You must check for low-hanging power lines, tree branches, or garage eaves before the truck arrives at your construction site.

How many people do I need to unload a full truckload?

For a 10-yard pour, you should have at least 3 to 5 people to help with spreading, leveling, and finishing. Attempting to unload a full truck with too few people will result in expensive standby fees.

Can I order concrete by the bag instead of a truckload?

For very small jobs like a single fence post, 80-pound bags from a home improvement store are more practical. However, it takes about 45 to 50 bags to equal just one cubic yard, making trucks better for larger projects.

What is a “hot load” in the concrete industry?

A hot load refers to concrete that has been in the truck too long or has gotten too warm, causing it to set rapidly. These loads are difficult to work with and may be rejected at the job site.

Why does the truck drum rotate during travel?

The rotation keeps the aggregates, cement, and water from separating. It also prevents the concrete from beginning the hydration process and hardening before it reaches the site.

Are there environmental rules for cleaning the truck?

Yes, drivers are not allowed to wash out their chutes or drums into storm drains because the high pH level is harmful to the environment. You must provide a designated washout area or pit on your property.

How wide is a concrete truck?

Most standard mixers are about 8.5 to 9 feet wide. You need to ensure your gates or entryways provide at least 10 feet of clearance for the vehicle to pass through safely.

Can I get concrete delivered on the weekend?

Many ready-mix plants operate on Saturdays, but they often charge a “Saturday premium” fee. It is rare to find delivery services on Sundays unless it is for a major industrial project.

What is the “yield” of a concrete load?

Yield refers to the actual volume of concrete produced from the raw materials. Sometimes factors like air entrainment can cause the yield to be slightly more or less than what was calculated.

Does weather affect the cost of the truckload?

In winter, plants may charge a “winter heat” fee to cover the cost of heating the water and aggregates. This ensures the concrete arrives at the site at a temperature that allows for proper curing.

How do I know if the truck is actually full?

The delivery ticket provided by the driver will list the exact yardage loaded at the plant. You can verify the volume by checking the batch weights of the Portland cement, sand, and stone listed on the receipt.